IMC For Steering Wheel Pigment Colour Paste

IMC For Steering Wheel Pigment Colour Paste Specification

- Product Name

- IMC For Steering Wheel Pigment Colour Paste

- Product Type

- Pigment Colour Paste

- Material

- Pigment Paste

- Color

- Variety of custom colors (as per customer requirement)

- Application

- Steering Wheel Colouring & Moulding

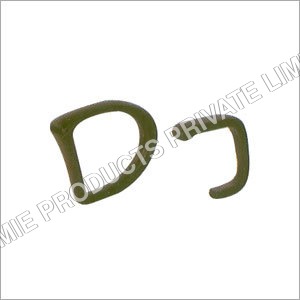

- Shape

- Paste

- Density

- 1.25 Gram per cubic centimeter(g/cm3)

- Storage Condition

- Cool, dry place away from direct sunlight

- Package Size

- 1 kg, 5 kg, 25 kg containers

- Viscosity

- Typically 20008000 cP (at 25C)

- Light Fastness

- Good (Varies by pigment)

- Shelf Life

- 12 months (unopened, stored below 30C)

- Compatibility

- Suitable for PU, PVC, and similar polymers

- Method of Use

- Add directly to polymer mix as recommended

- Heat Stability

- Up to 220C

About IMC For Steering Wheel Pigment Colour Paste

We manufacture In Mold Coatings of various Colors for PU application on Metal Alloy and composite Molds. It is mainly used for application of surface furnish of Polyurethane foams in the manufacture of flexible moulded foam, steering wheels, armrests, NVH parts, toys etc.

We also have special IMC for footwear Industry providing variety of unimaginable finishes.

Enhanced Colour Consistency for Steering Wheel Manufacturing

IMC For Steering Wheel Pigment Colour Paste provides manufacturers with a highly stable and homogenous colorant solution, ensuring top-tier consistency and performance in steering wheel applications. Its specialized formulation enables smooth blending with PU, PVC, and similar polymers, making it a versatile choice for diverse production needs. Custom color matching further tailors the appearance to individual customer specifications.

Reliable Heat Stability and Light Fastness

Engineered for demanding automotive environments, this pigment paste withstands heat up to 220C and maintains good light fastness. This ensures that installed steering wheels retain their vibrant appearance and resist fading, making it a dependable option for both aesthetic appeal and lasting function.

Simplified Application and Flexible Packaging

IMC pigment paste is simple to usejust add directly to your polymer mix as recommended for optimal color dispersion. Available in a range of package sizes from 1 kg to 25 kg, it is suitable for operations of any scale, from pilot runs to full production lines.

FAQs of IMC For Steering Wheel Pigment Colour Paste:

Q: How should IMC For Steering Wheel Pigment Colour Paste be incorporated into the production process?

A: This pigment paste is designed for direct addition to your PU, PVC, or compatible polymer mix. It disperses easily, providing a uniform color result when dosed according to your specific application requirements.Q: What are the benefits of using this pigment paste for steering wheels?

A: The primary benefits include high color consistency, excellent dispersion, heat stability up to 220C, and good light fastness. These features ensure that the final steering wheels display vivid, lasting colors tailored to custom requirements.Q: When and where is it best to store the unopened pigment paste?

A: For optimal shelf life, keep the unopened containers in a cool, dry place below 30C, away from direct sunlight. Under these conditions, the paste remains stable for up to 12 months.Q: What types of polymers are compatible with this pigment color paste?

A: The IMC pigment paste is suitable for use with polyurethane (PU), polyvinyl chloride (PVC), and similar polymer matrices commonly used in steering wheel manufacturing.Q: Can I order custom colors for the pigment paste?

A: Yes, this pigment paste is available in a variety of custom colors to match specific customer requirements. Contact the supplier or manufacturer to provide your shade preferences.Q: What package sizes are available for IMC For Steering Wheel Pigment Colour Paste?

A: This product is offered in 1 kg, 5 kg, and 25 kg containers. The various sizes accommodate both small batch and high-volume production settings.Q: What is the recommended method for applying the pigment paste in steering wheel production?

A: Add the required amount of paste directly into the polymer blend, ensuring thorough mixing for even distribution and strong color development. Follow your formulations recommended dosage for optimal results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in In Mold Coatings Category

IMC For ARM Rest & Integral Skin Foam

Shape : Rectangular

Color : Black

Product Name : IMC For ARM Rest & Integral Skin Foam

Application : Automotive, Office Chair, Furniture

Material : Integral Skin Foam

Product Type : Arm Rest

IMC For Shoe Sole

Shape : Granules

Color : Off White

Product Name : IMC For Shoe Sole

Application : Shoe Sole Manufacturing

Material : Polyvinyl Chloride (PVC)

Product Type : Compound

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS